Bottle and Can Crusher for Recycling Machines

Want to increase the competitiveness of your recycling machines? Invest in a durable crushing component that will serve your clients longer thanks to its longevity.

-

On-time Deliveries

-

Ruggedness and Durability

-

Competitive Price

-

Demo Versions

While crushing PET bottles and aluminum cans in recycling machines might seem like a rather primal task, it is far from that.

Designing a device to fulfill this task efficiently and without any stoppages requires a lot of sophistication.

Luckily, we know how to do it in a proper way.

Significant reduction of waste volume, easier transportation of raw materials for recycling, and permanent destruction of packaging to prevent its wrongful use. All of that is facilitated by a crusher, an essential part of any recycling machine. But what makes a crusher truly reliable…?

The Crusher – A Crucial Part of the Recycling Machine

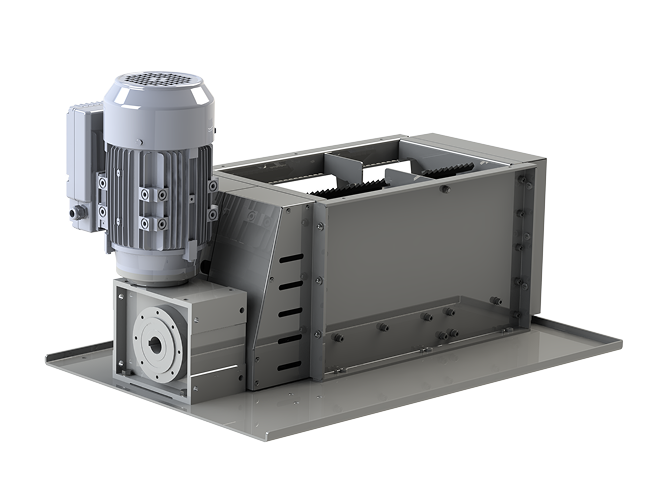

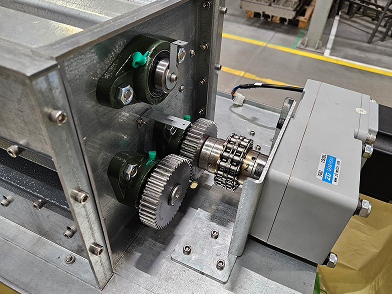

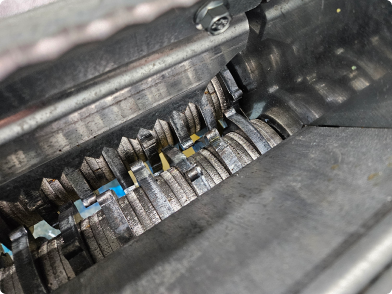

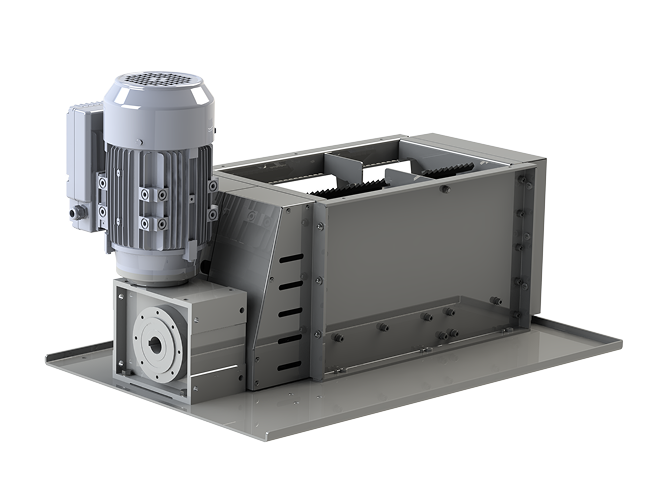

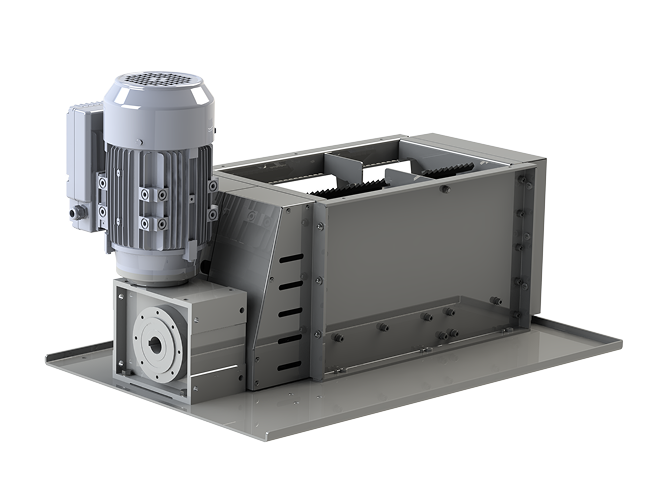

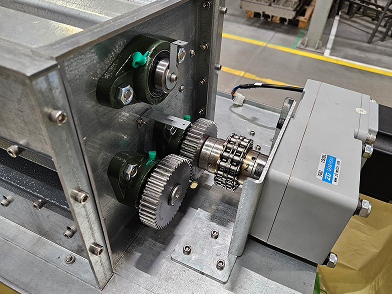

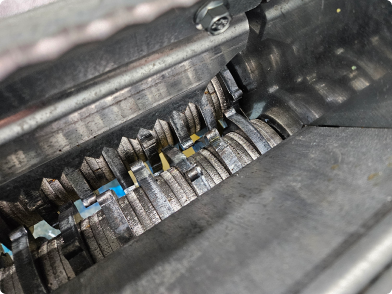

Our device crushes packaging using two rotating shafts with teeth, the main driven one and a secondary one coupled to it. A special gear motor ensures correct rotation speed and force. All of this, combined with the third shaft above the other two, allows for smooth operation without jamming.

RR Crusher is designed for crushing PET plastic bottles with a capacity of up to 3 liters and aluminum cans of up to 1 liter and can fit packaging of various sizes. While it is primarily meant for use in the recycling machines, its compact design allows for easy implementation in various working environments, regardless of the application. Since it does not require complicated commissioning or integration, RR Crusher can operate as a stand-alone crushing module and it can also be successfully adapted to other waste processing systems and processes.

-

capacity

100 pcs./min.

-

pet bottle processing

Up to 3L

-

aluminum can crushing

Up to 1L

-

power/torque

750W/145 Nm

-

packaging diameter

40-130 mm

-

packaging height

70-360 mm

Designed with the actual requirements of the deposit return system in mind, RR Crusher offers far better value for money than its competitors. With the added possibility of customization and easy integration with various projects, it is a solution truly dedicated to reverse vending machines (RVM).

-

Significant Reduction in Waste Volume

RR Crusher allows more processed packaging to fit in the container and makes it easier to transport raw materials.

-

-

Provides an Increased ROI

Due to its durable design, RR Crusher offers extreme longevity and makes it possible for companies to achieve higher ROI.

-

-

Permanent Destruction of Packaging

Prevents the reuse of processed packaging, e.g., by attempting to rescan the barcode and obtain an undue deposit refund.

-

What Does the RR Crusher Process Look Like?

- Used packaging collection

- Crushing the containers

- Transfer of raw materials

Purpose-built, Yet Incredibly Flexible and Adjustable

-

Compliant with technical requirements

-

Fully customizable to various client needs

-

Competitively priced, high value for money

-

Extremely durable and reliable

-

Easy to integrate with a wide range of machines

-

Compactly-sized and modular

-

Quiet operation, does not exceed 80 dB

Technical Data

Dimensions and weight

-

With base and drive

750 x 490 x 440 mm

-

Crushing module

445 x 300 x 265 mm

-

Weight with drive

51 kg

-

Weight without drive

29 kg

Power supply

-

Voltage

230 V (AC)

-

Frequency

50 Hz

Performance

-

Motor power

750 W

-

Torque

Approx. 145 Nm

-

Capacity

Up to 100 pcs./min.

We’ve a Refined Way to Your Project’s Success

From the initial contact, through crusher selection and customization, all the way to deliver – what does the process look like?

-

1. Contact and needs analysis

After you reach out to us, we will carefully listen to your needs and analyze the best possible solutions for your application.

-

2. Crusher selection and customization

Based on the needs analysis, we will choose the appropriate crusher version and, if necessary, customize it even further.

-

3. Production of the selected crusher

Having established the final requirements, we will proceed with the production of your customized crusher variant.

-

4. Delivery and support

The delivery of your crusher is not the end of our cooperation – afterward, we can provide you with service support and spare parts.

Effectiveness and Durability Proven in Testing

-

Bench Testing

Performed using various gear motors, RR Crusher module processed 720 PET containers and 620 aluminum containers.

-

RVM Machine Testing

In testing, our RR Crusher module processed 3,952 PET containers and 1,284 aluminum containers.

-

Destructive Testing

Performed using materials not intended for this device (styrodur XPS, metal sheets, and pieces of brick).

Up your competitiveness!

Every day, we step into our Dojo to design autonomous retail solutions inspired by what makes us human.